𐄀 Technology Connection to Future

The electric coupler is Plug-Socket interconnection structure, which is composed of a flip assembly, a shell assembly, an insulator assembly, a cable assembly and rear accessories. The contacts are of the elastic end face and pinhole type.

Yonggui Electric current commonly used electric coupler core numbers include 32, 40, 46, 50, 60, 70, 75, 89, 105, 140, 164, 196, 202, etc. It can provide rail connectivity solution with different structures and core numbers according to user needs. The electric cable connectors couplers adopt different specifications of elastic end contacts or pinhole parts to meet the application requirements of different voltages and currents. It integrates various signals such as power supply, control and communication, and has the characteristics of high technical content, reliable contact, easy installation and fast maintenance.

With the rapid development of information technology, the railway system has higher and higher requirements for network signal transmission. For this reason, the electric coupler can simultaneously add Ethernet function modules to provide 100Mbps and 1000Mbps network transmission. Ethernet module has the characteristics of stable and reliable signal transmission, convenient installation, and front-end maintenance.

The electric couplers from Yonggui Electric are currently used in hundreds of projects at home and abroad. Electric cable connectors couplers have various structures and good application effects. The domestic electric coupler market share reaches more than 65%.

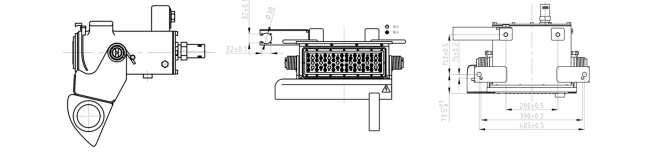

YG1110 Electric Coupler

YGC1121

Name | Diagram |

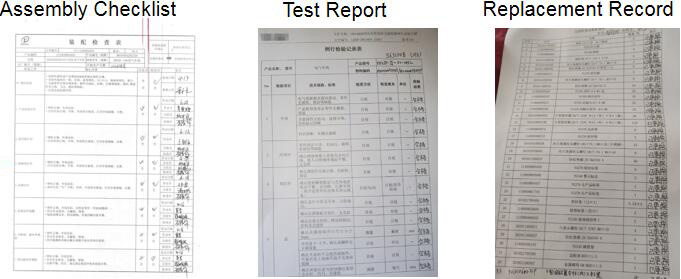

Confirmation of Technical Status Check and record Following Items: 1. Wiring Principle, 2. Overall Size, 3. Electrical Performance, 4. Customer Label Content 5. Contact Status. |  |

Disassembly and Clean Disassemble the E-coupler which was inspect with above items, the clean the parts, recover the appearance. The whole process of disassembly shoule be recorded. |  |

Repair or Replacement of Core Elements Evaluation, repair, replacement for core elements (such as isolators, contacts, cable assembly) . The whole process should be recorded. |  |

Re-Assembly and Step Confirmation Re-assemble together of all elements and components which were refreshed according to reverse sequence of disassembly record. Confirm whole process with assembly record. |  |

Routine Test and Document Files Following test items should be performed: 1. Appearance Inspection 2. Electrical Performance 3. Mechanical Performance 4. Assembly Inspection Test reports should be documented with replacement report and assembly checklist together for auditing. After maintenance service, the E-coupler should meet the criteria of technical agreements. |

Tailoring connectors to your unique needs.

Provide systemic solutions

Respond to needs within 12 hours