𐄀 Technology Connection to Future

Axle counters are an integral part of railway signalling systems, ensuring the safe and efficient operation of trains. These devices play a crucial role in accurately counting axles and detecting train movement. In this article, as one of the most realible electrical connectors manufacturers, we will delve into the world of digital axle counters, exploring their working principle, installation process, and the importance of choosing the right manufacturer.

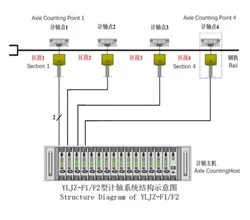

Axle counters form a vital component of railway signalling systems. They are responsible for providing accurate information about the presence and movement of trains on the tracks. By counting the number of axles passing over a particular section of the railway, axle counters enable efficient management of train traffic. They contribute to the safe operation of trains by ensuring appropriate signaling and avoiding collisions.

The working principle of axle counters revolves around the detection and counting of axles. Axle counting is typically done by using sensors placed on the tracks. These sensors generate impulses when an axle passes over them. The impulses are then processed and converted into a count. The digital axle counter provides real-time information on train occupancy, helping the signaling system to make accurate decisions.

Axle counters use various technologies like inductive loops, strain gauges, or fiber optic sensors to detect axles. These technologies differ in their accuracy, reliability, and installation complexity. However, no matter the technology used, the ultimate goal remains the same – to detect and count axles precisely.

Installing axle counters requires careful planning and execution. The sensors need to be placed at the right locations to ensure accurate detection of axles. They should be installed at appropriate distances from the start and end of the counting zone to eliminate any errors. Additionally, the wiring and connections must be properly set up to ensure reliable data transmission.

During the installation process, it is crucial to follow the guidelines provided by the digital axle counter manufacturer. Each manufacturer may have specific instructions and requirements for installation. Adhering to these guidelines helps ensure the optimal performance and longevity of the axle counters.

Choosing the right digital axle counter manufacturer is essential to ensure the reliability and effectiveness of the signaling system. A reputable manufacturer will design and produce axle counters that meet stringent quality standards. Their expertise and experience in the field will ensure that their products are accurate, durable, and suitable for railway applications.

When selecting a digital axle counter manufacturer, it is crucial to consider factors such as product quality, customer support, and industry reputation. Reading reviews and gathering feedback from other railways or experts can help make an informed decision. It is advisable to choose a manufacturer with a proven track record and a strong commitment to delivering reliable and innovative solutions.

In conclusion, digital axle counters are vital components of railway signaling systems. They enable efficient management of train traffic by accurately counting axles and providing real-time information on train occupancy. The correct installation and choice of the digital axle counter manufacturer are crucial to ensure reliable and accurate operation. By selecting a reputable manufacturer like Yonggui, railways can enhance their signaling systems and improve the safety and efficiency of train operations.