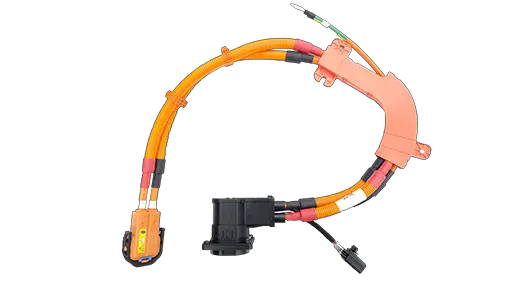

Assist in the creation of manufacturing schematics, bill of materials (BOMs), and job instructions to guarantee precise and effective production. Simplify procedures like wire cutting, stripping, crimping, and assembly to cut down on errors, waste, and boost output all around.