𐄀 Technology Connection to Future

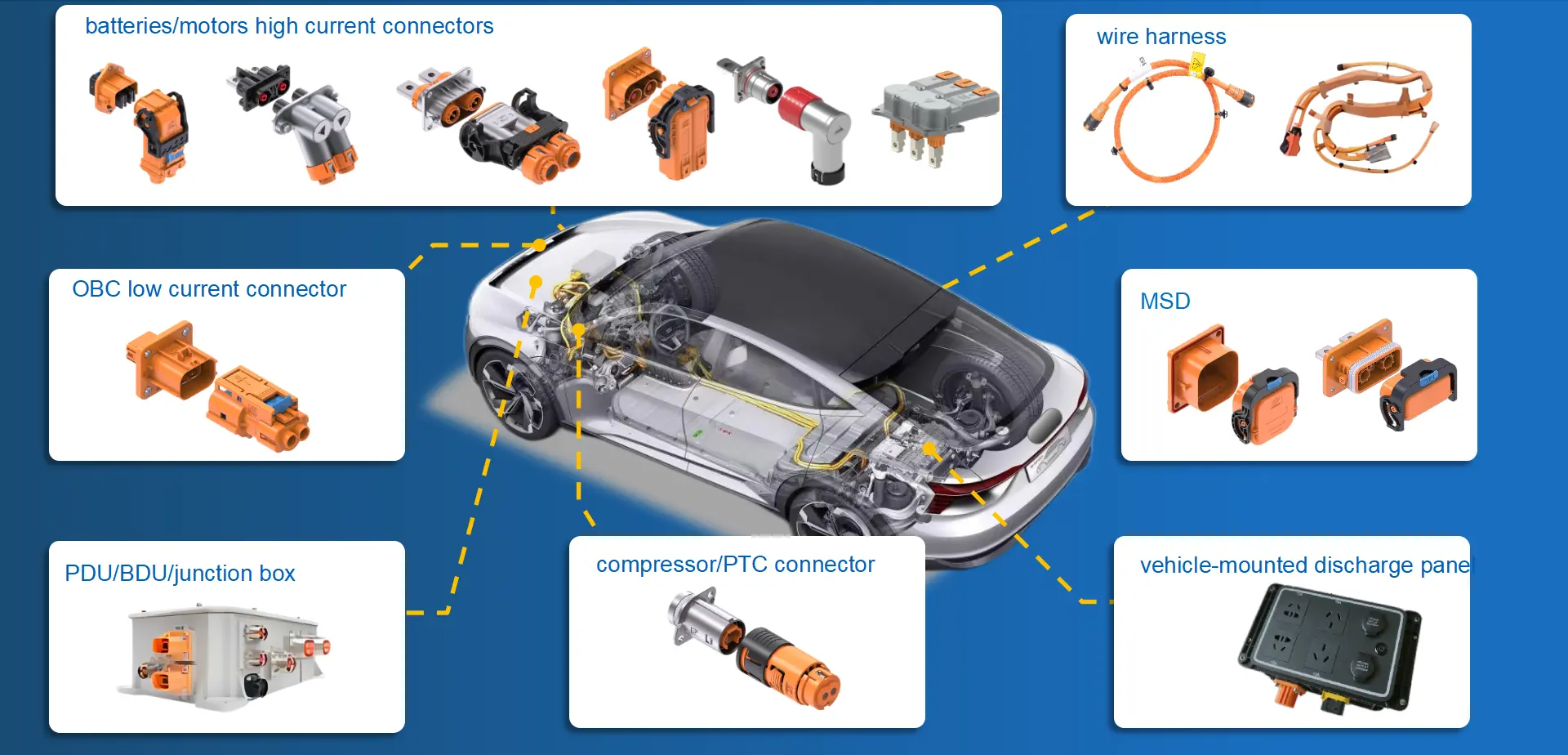

In the field of electric vehicles, Yonggui Electric provides the whole solution of high voltage, large and small current interconnection system. Main products: high-voltage interconnection system connectors and harness components, high-voltage power distribution box, etc.The products adopt ultrasonic welding, high-speed punching terminals and other process technologies to realize lightweight products. On the basis of IATF 16949 system, the introduction of VDA system, MES system, automation, integration of electrical performance testing and other process control methods, as well as dust-free workshop and other modern production environment, to provide strong quality assurance for the products.

Connectors for new energy vehicles play a key role in power transmission, data communication and control systems. To ensure the reliability and performance of new energy vehicles, the maintenance and durability of vehicle connector are critical.

Regular inspection and cleaning

Tightening and plug-in precautions

Keep dry

Number of plugs and unplugs

Material quality

Design optimization

When selecting connectors for electric vehicles, a number of factors such as the type of connector required, environmental requirements, and performance specifications need to be considered to ensure that it meets the requirements of a particular application. After determining the type product, you can then refer to the following parameters for selection:

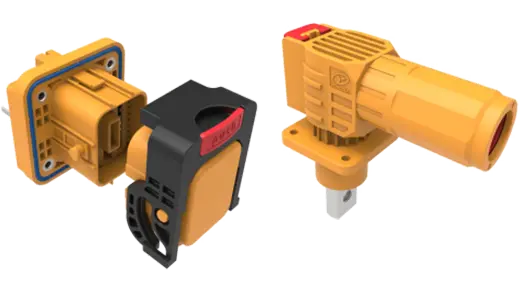

In the development of new energy vehicles in recent years, automotive high-voltage connectors are gradually separated from the traditional high-voltage high-current and traditional low-voltage automotive connectors.

Compared with the traditional high-voltage high-current connectors, the use of connectors for new energy vehicles is more complex and changeable working conditions, the reliability of the connector requirements are also higher. Due to the increase in voltage level (the current mainstream system voltage ≥ 300V DC), the connector's safety requirements are higher, and accordingly, the insulation and protection requirements of the product have been improved.

Support full set of products customized development

Refer to the product details page

Contact us for information

Subsequent platform products are stamped leaf spring structure terminals.

We use cold crimping or ultrasonic welding to connect the wires.

At present, we mainly test our products according to USCAR standard, if customers have special requirements, please contact us to add other standard tests.

Contact us to get the corresponding information

Tailoring connectors to your unique needs.

Provide systemic solutions

Respond to needs within 12 hours